1. Insert the acid-treated tube into the mandrel so that it has an even circular shape as a whole

Pat lightly with a rubber hammer or wood hammer to spread.

2. Remove the silver lead that has been thickly mounted on the surface of the tube by stringing.

If the silver lead remains thick, in the process of straightening the tube

The surface cries heavily or causes severe curvature inside the tube.

3. Put it back on the mandrel and straighten it with a metal rod.

4. Repeat by warming up from time to time.

5. Repeat until the tube has a certain size of taper

This work has the same effect as forging and rolling.

6. When the necessary dimensions are reached,

line (in the order of yellow wood, medium wood, detail, and driftwood)

Grind the surface thoroughly and use sandpaper to sand the inside

and outside of the tube Grind evenly.

7. This tube is made so that the inner diameter matches the shape of the mandrel

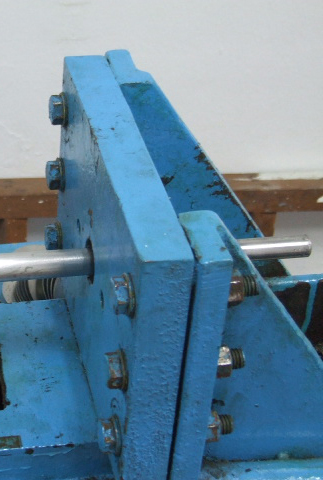

Press using a press machine or a drawing machine.

8. Finish with fine sandpaper and cut both sides.

Comments

There are no comments to display.

Comments can be added by Administrator only.